Matti Monojet 108 (4.25"), 216 (8.5") and 557 (22") Imprinting Systems

Please contact us for distribution in Europe! If your company has sales and service capability, then we should talk. Here is our contact form.

Introduction

The Matti Monojet 108 (4.25") and 216 (8.5") imprinting systems are part of a much broader family of imprinting systems, all offering cost-effective, innovative and reliable solutions suitable for many marking applications.

Each solution can be customised to meet specific business needs. The Monojet 108 and 216 are full-featured standalone economic solutions, designed for web speeds of up to 300 meters/min and offering inks for coated and uncoated stocks. The 3 level greyscale allows for high-quality picture reproduction.

One base unit can drive up to four 4.25" or 8.5" printheads. The base unit can drive two Matti NIR / IR dryers by means of a driver module that can be installed. This ensures optimal communication between the printheads and the dryer which guarantees the best possible efficiency.

Our Imprinting Systems bring hybrid printing to the next level. They can be easily integrated into web presses, sheet presses or large flatbed systems.

The solution provides inks to print on coated, uncoated and flexible materials. Specialty inks are available to print MICR or fluorescent security features.

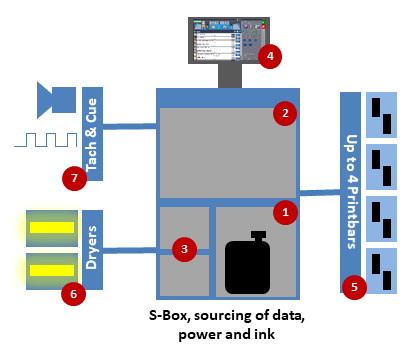

System Overview

The Matti Imprinting Solution is designed as a full system with multiple components that can be combined. The central element is the S-Box, sourcing data, power, and ink to the printheads. All data processing is done on the S-Box, including RIP, queue management

The S-Box contains / drives all required components of the system in one convenient cabinet:

- Ink delivery system, including conditioning of the ink

- Control electronics

- Optional driver modules for up to 2 Matti IR / NIR / UV modules

- Digital Frontend with mono RIP, queue management and system overview

- Up to 4 Printbars, connected to the S-Box via umbilical (contains power, data and fluids)

- Up to 2 IR / NIR / UV modules connected to the S-Box - up to 560mm width and 12kW power for each module

- Input for external tach and cue signals

The Printbar

The Monojet printbars are compact and versatile, yet they are of industrial build quality. All fluid and electrical connections are conveniently placed on the backside with easy service access. Two handles allow carrying the unit - ideal for dynamic environments where many different jobs are run.

The ink supply system is located close to the inkjet heads, allowing for best and tight control of ink temperature and pressure control.

The printbar can be populated with either 1 (Monojet 108) or two (Monojet 216) inkjet modules.

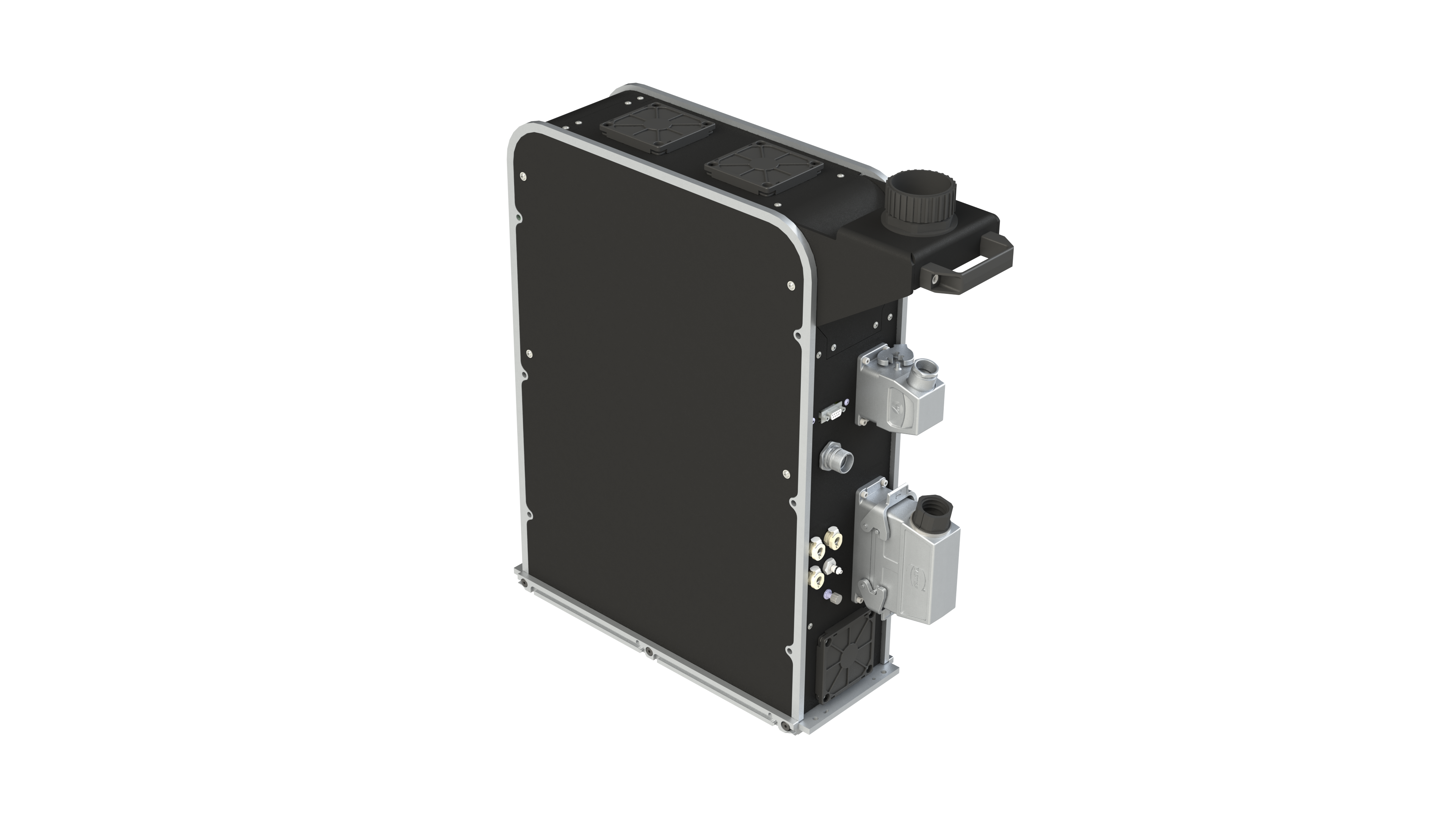

The S-Box

The S-Box sources the ink, electrical power and data to the attached printbars. It also contains the digital frontend for the operator, where the system is controlled and supervised and where the print queue is managed.

Optionally, the S-Box can drive the Matti NIR and IR dryers - up to two dryers may be attached.

The S-Box provides space for ink and cleaner fluids.

Combination with the M-Tower

The Matti imprinting solution can ideally be combined with the M-Tower to build a powerful inkjet mono press that can easily replace legacy toner continuous feed printers. The M-Tower provides a paper transport that can be configured either for simplex or for duplex operation. Each M-Tower accepts up to two imprinting printbars. These may be stitched or driven in lanes.

The M-Tower section contains more information.

| Name | Version | Size | Modified | ||

|---|---|---|---|---|---|

|

Monojet 216 (8.5") hot | 4.0 | 945.49 KB | 1 yrs ago | Download |

Technical Data

- The Matti Monojet is a fully standalone imprinting system. It contains a base unit that accepts 5, 10 or 20 liter ink containers, preconditions (degassing and filtering) the ink and delivers the ink to the printheads.

The base unit can drive up to 4x Monojet 108 or 4x Monojet 216 printheads.

Additionally it can drive the Matti NIR / IR or UV dryers.

The system comes with a PDF enabled digital front end (DFE) that controls the entire system. All parameters are visible via this DFE. - Compatible with a wide range of stocks, coated and uncoated

- Different inks for best TCOP

- Standalone design

- Base unit can drive two dryers (NIR, IR, UV)

- PDF input

- Easy to operate

- Easy maintenance

- Upon request, built in remote support router

- Resolution: 600 or 1200dpi

- Drop on demand inkjet

- Drop sizes: variable, up to 12pl

- Recirculating ink supply

- Compatible inks: Matti aqueous pigment and dye ink, Matti UV ink

- Maximum web speed: up to 300m/min (at lower resolution)

- Touch screen control

- Buckets for integration into legacy offset or flexo presses can be custom designed and provided

- The Monojet imprinting modules can be integrated via the Matti M-Tower and the MCR-1000 substrate transport.

- Can be combined with the Matti IR / NIR dryers, up to 12kW

- Can be combined with Matti UV curing systems

- Custom interfaces to SQL databases or ERP systems can be built and integrated for variable data printing

- Different aqueous inks for uncoated media

- Different aqueous inks for coated media

- UV inks

- Security inks

- MICR inks